SEMICONDUCTOR SORT/TEST CUSTOM APPLICATIONS SAMPLER

(Just click on any thumbnail photo below for a bigger picture)

- Except where noted, most sort code was written purely in standard Perl/tk (a defacto standard for the sort area), together with ODBC(windows) and DBI(unix) database interfacing.

- Unix server based data processing code was written in Perl, and could run either on a desktop PC (for easier debugging) or Solaris Unix (for production).

| Tool | Problem | Sample Screenshots/Information | |||

| Functional Test: Versatest 2104 Reverse engineer embedded code, rebuild & enhance for automatic die retesting |

If a test site fails too many times, automatically shift the probe card over and see if retesting will yield a better result using different pins. Reverse engineered and reworked old yet critical C language Dos/Desqview code, and ported to a Turbo C/C++ compiler for easier debugging. Reworked low level rs232 interfacing to EG and KLA probers. Payback was approx $5K/wk in recovered die. Also revised main screen to include test site deltas per operator requests. |

|

Sample User Documentation |

Sample Project Management Documentation While this project had many more memos, formal reviews, and specification changes than are shown below, these are some typical Waterfall documents.

|

|

| Optical Inspection: Camtek Falcon Data Data Integration & Transfer Integration of optical inspection with the sort floor |

Integrated a Camtek Falcon optical inspection tool by retrieving recipes from server based on device type. Polled for and renamed (based on device type and test step) Camtek Falcon output maps, recombined/formated them with other map information and forwarded the new optical inspection maps to server. |

|

|||

| EPROM UV Erase Monitoring | Interfaced to the tool, and (based on product type and processing step) prohibited the erasure of eprom wafers that should leave the sort floor programmed. |

|

|||

| Data Bake Oven Monitoring | Engineering reworked the databake ovens with low cost Yokogawa UP550 controllers. Wrote the RS232-422 interfacing in minimal time (using Perl/tk). Tracked and stored data and stopped further wandins if the last run was out of spec. Real time displays are shown for several ovens. A pink background means the run had a problem and further wandins are disabled until engineering clears the oven via the software. |

|

|

||

| Wafer Correlation: Excel Map Correlation Macro |

Overlaid test bincodes from two wafer maps for tester and test program correlation, and created bincode shift table. |

|

|

||

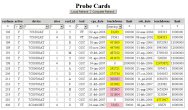

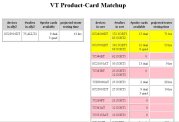

| Probecard Availability Prediction | Based on what was coming through the final processing steps in the fab, machine states and probecard inventory, this webpage utility predicted how much could be produced. The probecards gated production. Written in HTML and Javascript, and using ODBC queries. |

|

|

|

|

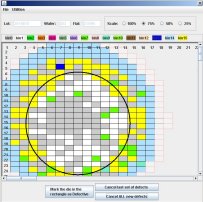

| Wafer Map Editor |

Developed a graphical user interface for the operators to easily reject scratched die and optionally added an exclusion ring to the edge of the wafer Converted the original Perl/tk application to Java SE, to hand off to corporate IS for further intersite updates. A prototype Flash (web) version is viewable on the kenfreed1.com homepage (under |

|

|

|

|

|

Inkless Wafer Maps Developed the wafer map enhancements and data flow (to assembly in the Philippines) so that wafers did not have to get physical ink dots on defective die. |

This was not as it might sound. There was a lot of error checking to make sure we were not mismatching maps to testing step and wafer (which would have made the wafer product useless scrap). This code was written in Perl/tk, using ODBC database access for PC desk debugging and DBI database access for the Unix(Solaris) production version. |

||||